Einfluss der Wälzlagerprofilierung auf Steifigkeit und Lebensdauer

Die FVA-Workbench dient als Wissensplattform, die das in den Projekten entstandene Forschungswissen der FVA für Ingenieurinnen und Ingenieure zugänglich und anwendbar macht. Das Lesen und Studieren unzähliger Seiten wissenschaftlicher Dokumentation entfällt damit und die Entwicklung innovativer Getriebe wird deutlich nutzerfreundlicher und effizienter. Im Folgenden wird die detaillierte Berechnung von Wälzlagern in der FVA-Workbench an Hand der Berücksichtigung der Profilierung von Rollenlagern gezeigt.

Jetzt die FVA-Workbench kostenfrei ausprobieren

Testen Sie den vollen Funktionsumfang der FVA-Workbench für 6 Wochen und überzeugen Sie sich selbst.

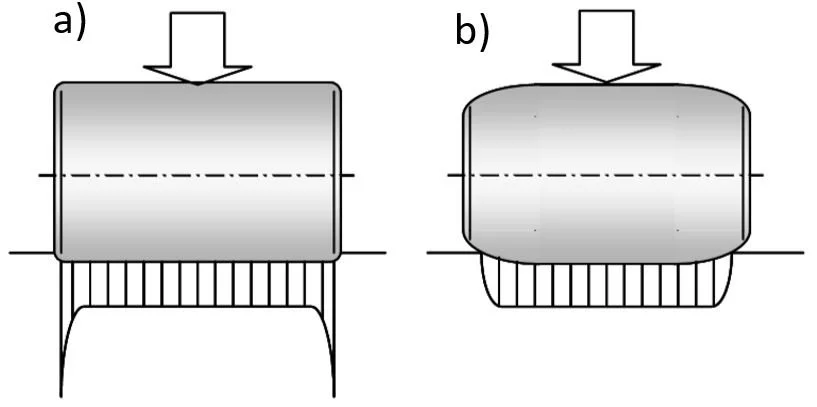

Bild 1: Pressungsverteilung a) ohne Profilierung und b) mit Profilierung // Quelle: A. Keßler: Schiefstellung und Axialschubverhalten von Zylinderrollenlager, Dissertation Universität Hannover (2010)

Profilierung von Rollenlagern

Bei Wälzlagern besteht Linienkontakt zwischen den Wälzkörpern und der Laufbahn. Sind die Wälzkörper ideal zylindrisch (Zylinderrollenlager) oder kegelig (Kegelrollenlager) führt dies im Kontakt der Wälzkörperstirnseite mit den Laufbahnen zu lokalen Pressungsspitzen (Bild 1a). Dies kann zu Schädigungen in Form von lokaler Pittingbildung in diesen Bereichen führen (Bild 2). Um diese Pressungsspitzen zu vermeiden, werden Wälzlager immer mit einer Profilierung entlang der Rollenlängsachse ausgeführt (Bild 1b).

Neben der Vermeidung dieser hohen Kantenspannungen hat die Profilierung auch Einfluss auf die folgenden Kriterien:

• Maximale Pressung im Kontakt Rolle-Laufbahn, insbesondere bei hohen Verkippungen

• Modifizierte Referenzlebensdauer nach DIN 26281 (Dynamische Tragzahlen und nominelle Lebensdauer - Berechnung der modifizierten nominellen Referenz-Lebensdauer für Wälzlager, Beuth Verlag (November 2010))

• Kipp- und Senksteifigkeit

Abbildung 2: Lokale Grübchenbildung als Folge der durch Verschleiß entstandenen Profilierung (Quelle: Ferdinand Wikidal/ Gear Consult)

Zylinder- und Kegelrollenlager haben typischerweise ein logarithmisches Profil gemäß DIN 26281. Die tatsächliche Höhe und Form der Profilierung kann jedoch erheblich davon abweichen und wird vom Hersteller, auf der Grundlage der verfügbaren Kenntnisse, für jeden Lagertyp festgelegt. Um den Einfluss verschiedener Profile auf die oben genannten Kriterien bei der Lagerauslegung zu berücksichtigen, bietet die FVA-Workbench die Möglichkeit, das Profil für jedes einzelne Rollenlager anzupassen. Zusätzlich zu den vordefinierten Profilformen können auch Profilkurven definiert werden, die vom Lagerhersteller zur Verfügung gestellt werden oder auf Messungen basieren. Es ist daher für kritische Fälle zu empfehlen, die endgültige Lagerauslegung in Abstimmung mit dem Lagerhersteller durchzuführen.

Berechnungsbeispiel

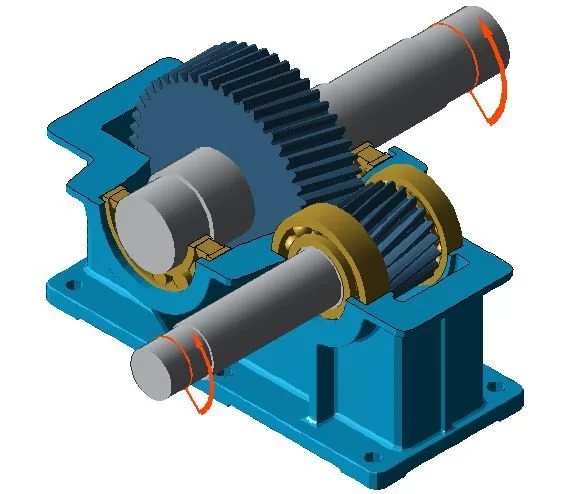

Der Einfluss verschiedener Profile wird anhand der Berechnung der motorseitigen Abtriebswellenlager des Typs NJ 230 aus dem in Abbildung 3 gezeigten Getriebe demonstriert. Für das Lager werden drei verschiedene Profilvarianten berechnet:

• Logarithmischen Profilierung mit einem Betrag von 32 μm (entsprechend DIN 26281)

• Logarithmischen Profilierung mit einem Betrag von 14 μm

• Keine Profilierung

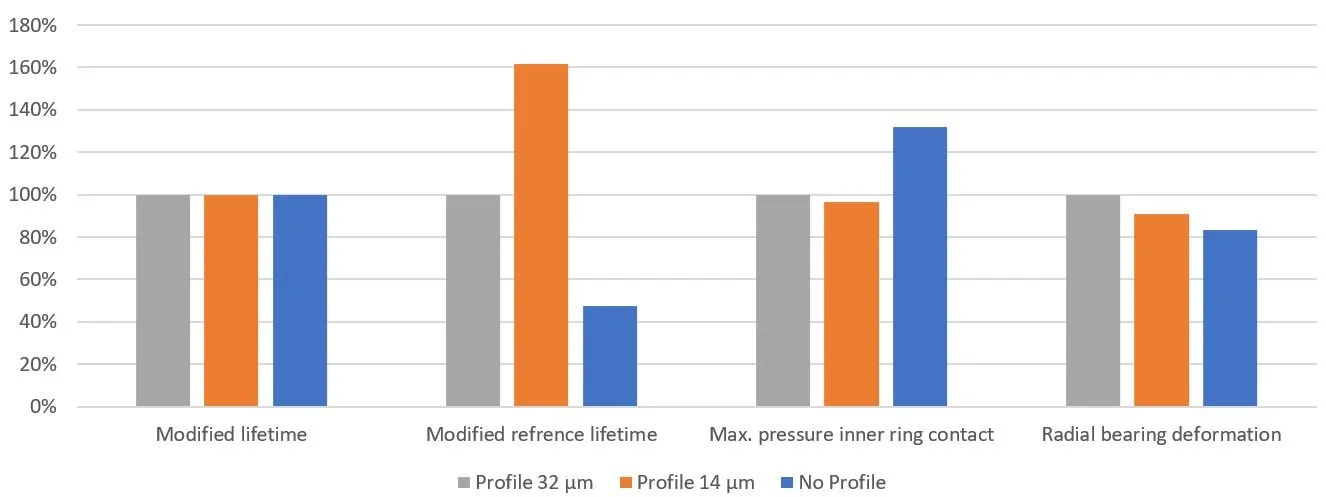

Diagramm 1 gibt einen Überblick über die Berechnungsergebnisse für die drei genannten Varianten. Die Werte sind jeweils auf die der Vorgabe in DIN 26281 entsprechende Profilierung (hier: 32 μm) bezogen.

Diagramm 1: Vergleich der Berechnungsergebnisse für unterschiedliche Profilierungsbeträge

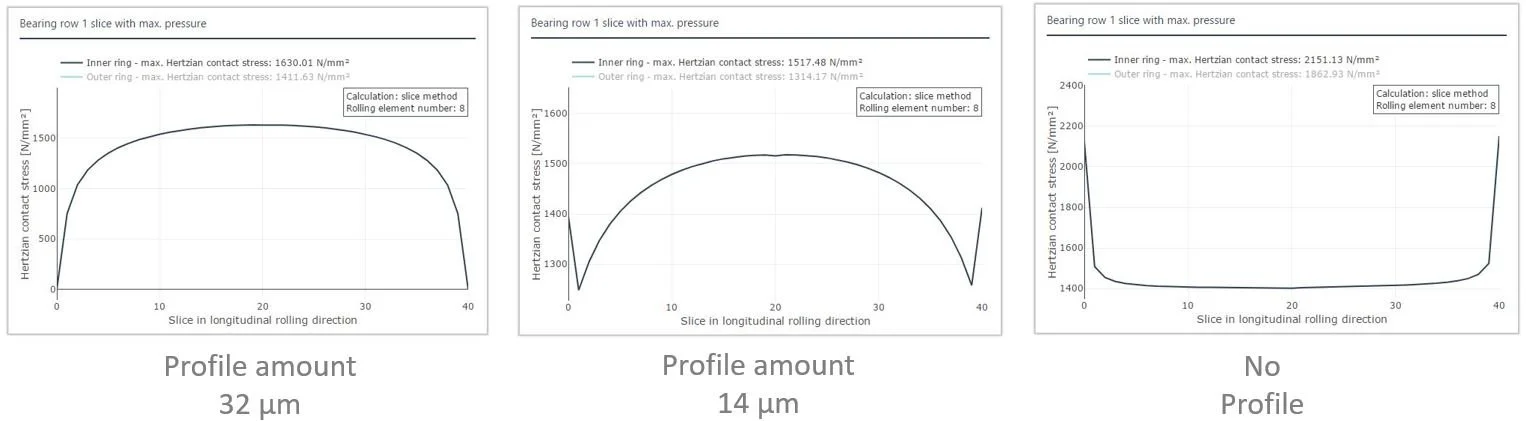

Zusätzlich wird die Pressungsverteilung entlang der Rollenlängsachse im Innenringkontakt des am stärksten belasteten Wälzkörpers für die drei Varianten in Bild 4 verglichen.

Bild 4: Vergleich der Pressungsverteilungen des höchstbelasteten Wälzkörpers

Was lässt sich aus den Ergebnissen ableiten?

• Die Profilierung hat keinen signifikanten Einfluss auf die Ergebnisse der erweiterten Lebensdauerberechnung (sowohl nach ISO 281 als auch nach den Katalogberechnungen der Lagerhersteller). Es können sich lediglich kleinere Unterschiede ergeben, wenn aufgrund der geänderten Lagersteifigkeit in der Gesamtsystemberechnung, leicht unterschiedliche Lagerkräfte berechnet werden.

• Die Verteilung und der Maximalwert der lokalen Kontaktpressungen in den Lagern werden durch die Vorgabe unterschiedlicher Profilierung entscheidend beeinflusst. Aus den Kurven in Bild 3 ist ersichtlich, dass die Pressung in der Mitte der Rolle mit zunehmender Profilierung ansteigt. Bei geringeren Profilierungsgraden wird die Pressungsverteilung gleichmäßiger. In diesem Fall können jedoch erhöhte Kantenspannungen auftreten, insbesondere bei hohen Neigungswinkeln.

• Da der Wert der modifizierten Referenz-Lebensdauer nach DIN 26281 auf der Berücksichtigung der lokalen Kontaktpressung beruht, ist auch hier ein starker Einfluss auf die Lebensdauerwerte für jedes spezifizierte Profil zu erkennen.

Jetzt zum Newsletter anmelden

Registrieren Sie sich für unseren Newsletter, um die neuesten Informationen zu Antriebstechnik Software, White Papers und Weiterbildungen zu erhalten.

FVA-Workbench Features im Überblick

Sie möchten mehr über die Funktionalitäten der FVA-Workbench erfahren? Hier finden Sie einen Überblick über die aktuellen Features.